Triveni Turbine Lube Oil Filter

Triveni is one of the leading Turbine manufacturers in India. They are known for manufacturing all types of turbines for different power units. We at Lufil Filtration Technology manufacture these turbine replacement filters. The main objective of using these elements is to remove unwanted dirt from the system. By Eliminating such contamination it helps to maintain the performance of the turbine.

Why Choose LUFIL brand Filters for Triveni Turbines?

We always focus on providing exact replacement of OEM Filters. Due to this many reputed steel manufacturers and power units consider LUFIL as their prime filtration partner. We use high grade material to match the same quality supplied by OEM. Which makes our turbine filters more capable of maintaining the pressure drop in the system while removing the dirt particles. We also provide customize cartridges for such system which can be cleaned multiple time by using SS wire mesh as media.

Mostly Used Filters Dimensional Details based on Flow Rate.

- 04 GPM Lube oil filter element

OD 92 mm x ID 15 mm X L 100 mm

Flow Rate: 04 GPM

Working Pressure: 6 Kg/cm2

Pleated media with outside supporting wire mesh

Single side open with top threaded connection

- 08 GPM Lube oil filter element

OD 92 mm x ID 15 mm X L 240 mm

Flow Rate: 08 GPM

Working Pressure: 6 Kg/cm2

Pleated media with outside supporting wire mesh

Single side open with top threaded connection

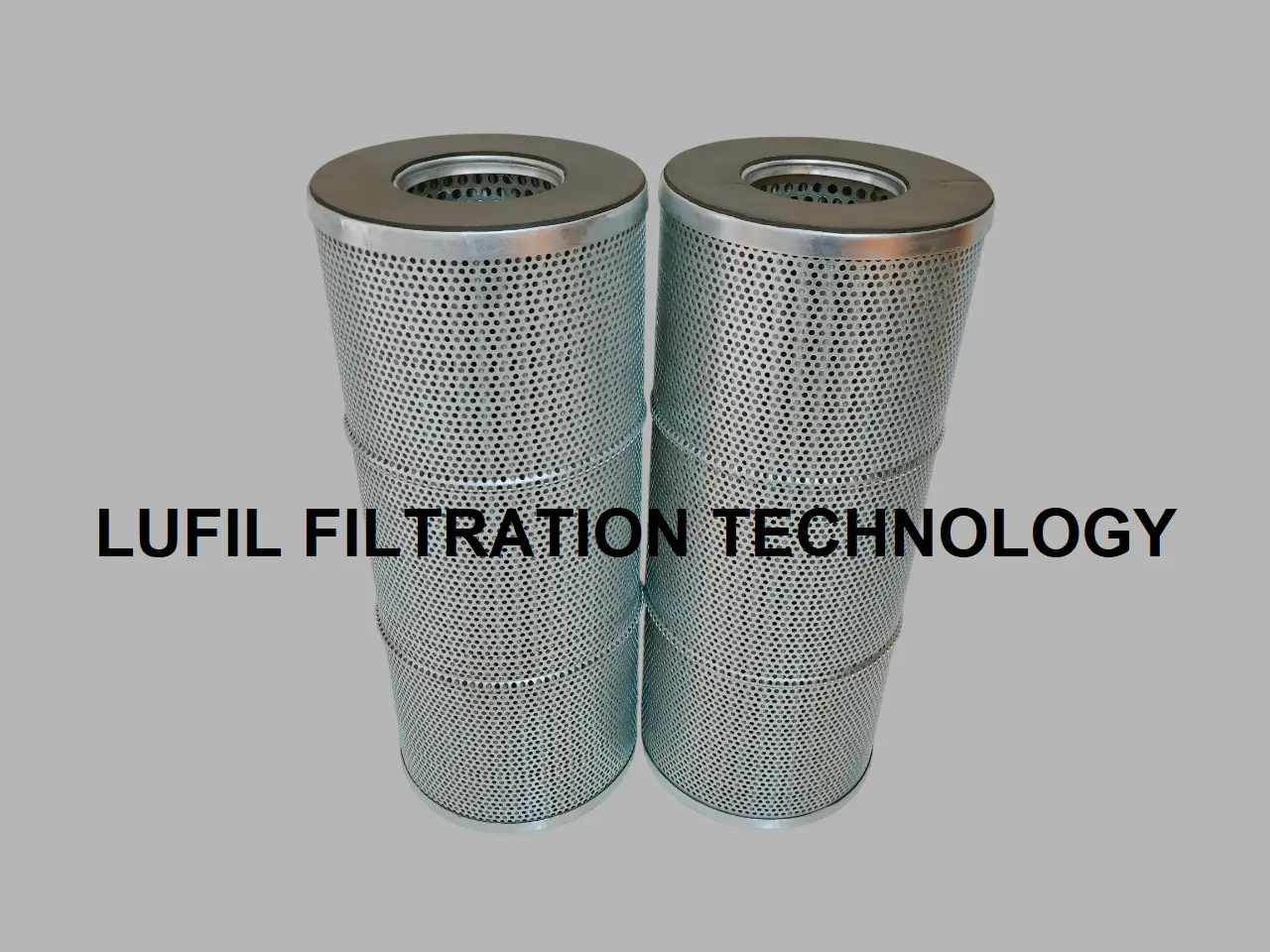

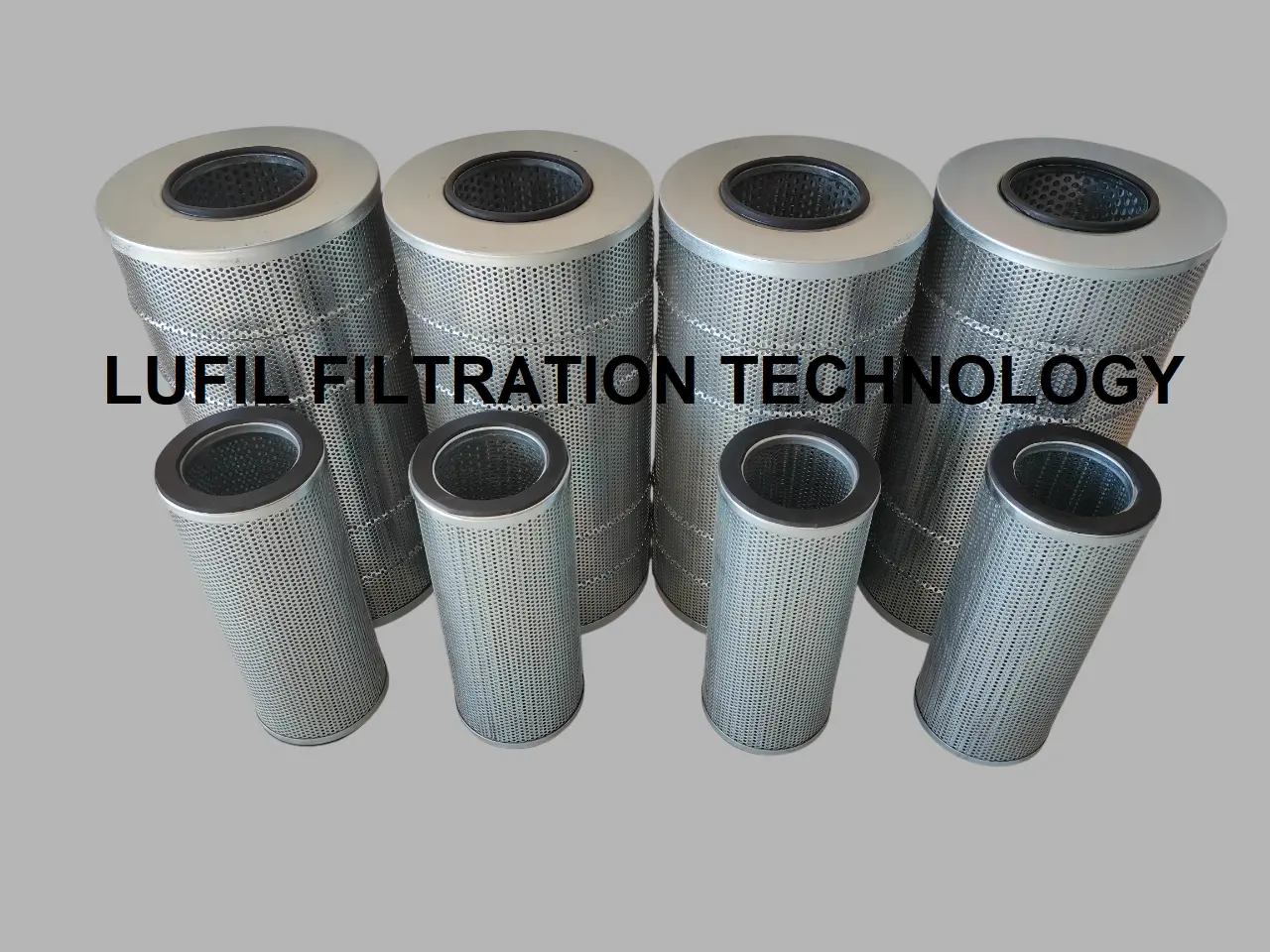

- 15 GPM Lube oil filter element

OD 140 mm x ID 50 mm X L 260 mm

Flow Rate: 15 GPM

Working Pressure: 6 Kg/cm2

Protected with inner and outer perforated cylinder

Both sides open with a rubber gasket

- 25 GPM Lube oil filter element

OD 180 mm x ID 83 mm X L 261 mm

Flow Rate: 25 GPM

Working Pressure: 6 Kg/cm2

Protected with inner and outer perforated cylinder

Both sides open with a rubber gasket

- 35 GPM Lube oil filter element

OD 180 mm x ID 83 mm X L 351 mm

Flow Rate: 35 GPM

Working Pressure: 6 Kg/cm2

Protected with inner and outer perforated cylinder

Both sides open with a rubber gasket

- 45 GPM Lube oil filter element

OD 180 mm x ID 83 mm X L 431 mm

Flow Rate: 45 GPM

Working Pressure: 6 Kg/cm2

Protected with inner and outer perforated cylinder

Both sides open with a rubber gasket

- 90 GPM Lube oil filter element

OD 225 mm x ID 100 mm X L 461 mm

Flow Rate: 90 GPM

Working Pressure: 6 Kg/cm2

Protected with inner and outer perforated cylinder

Both sides open with a rubber gasket

- 120 GPM Lube oil filter element

OD 225 mm x ID 100 mm X L 581 mm

Flow Rate: 120 GPM

Working Pressure: 6 Kg/cm2

Protected with inner and outer perforated cylinder

Both sides open with a rubber gasket

- 140 GPM Lube oil filter element

OD 270 mm x ID 125 mm X L 551 mm

Flow Rate: 140 GPM

Working Pressure: 6 Kg/cm2

Protected with inner and outer perforated cylinder

Both sides open with a rubber gasket

Technical Specifications

- Filtration Rating

10 μm, 15 μm, 25 μm, 50 μm, 100 μm

- Body Material of Construction

Zinc Coated MS, Powder Coated

- Operating Pressure

30 bar

- Filter Media

Glassfiber with supporting wire mesh, SS Wire Mesh, and Polyester (Imported Quality)

- Temperature Range

-30°C to +120°C

Advantages

Improve System Cleanliness.

Reduces maintenance costs.

Maintain system pressure drop.

Available at affordable rates.

Easy replacement options.

Applications

Power Generation

Petrochemical Plants

Manufacturing Industries

Refineries

Process Industries