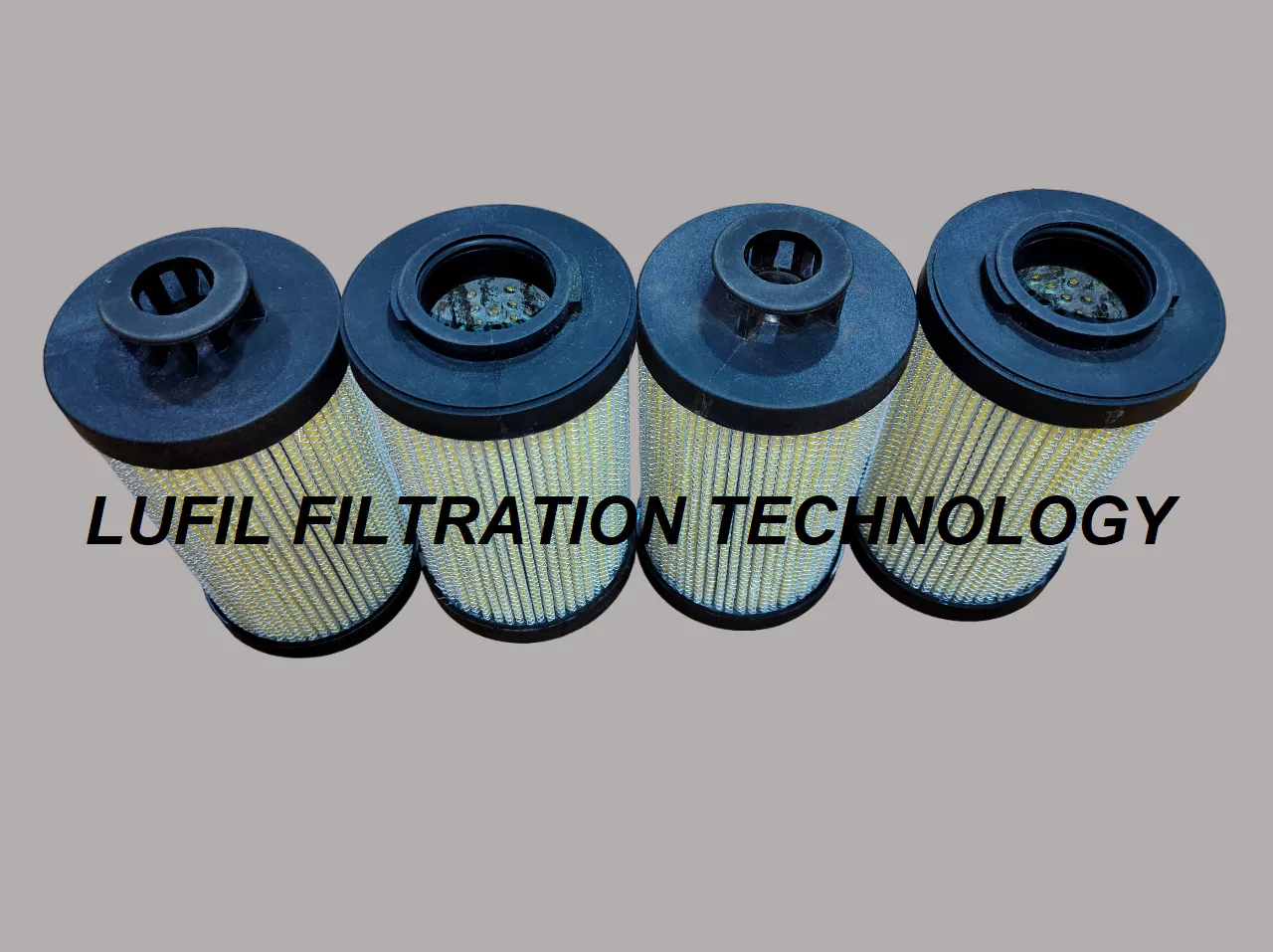

Return Line Filter

The oil flows to various hydraulic components, such as cylinders, motors, and valves. During this time interval, oil gets contaminated as it carries dirt before it reaches the tank. Dumping dirty oil into the tank is not safe as it forms sludge and deposits within the system. These deposits can obstruct flow passages, leading to potential blockages and malfunctions. To reduce the chances of blockage and to maintain cleanliness, return line filters are used.

Where Are Return Line Filters Installed?

These elements are installed at the return line of hydraulic systems just before the tank. This is the line through which the fluid gets back to the reservoir or tank after it has executed its intended function in the system.

Types of Return Line Filters

- In-tank Return Filters

These cartridges are installed directly inside the hydraulic tank or reservoir. They save space and are easily accessible for maintenance.

- Inline Return Filters

They are independent of the tank and can be placed at any point in the system, offering flexibility in system design.

- Off-line (Bypass) Filters

These filters are used in systems with a separate filtration circuit. They continuously filter hydraulic fluid without interrupting the main operation.

Technical Specifications

- Filtration Rating

3 μm, 6 μm, 10 μm, 25 μm, 35 μm, 50 μm, 100 μm, 150 μm Etc.

- Recommended Initial Differential Pressure For Design

7.25 PSI

- Flow Rate

05 LPM to 1400 LPM

- Bypass Valve Cracking Pressure

1.5 to 3 bar

- Operating Pressure

50 psi to 440 psi

- Filter Media

Glassfiber, Stainless Steel Wire Mesh, Synthetic Cellulose

- Temperature Range

-30°C to +100°C

Advantages

Protects hydraulic components from contamination.

Extends equipment life and reduces downtime.

Improves system efficiency and performance.

Reduces maintenance costs.

Enhances fluid cleanliness and reliability.

Easy maintenance and replacement options.

Applications

Hydraulic power units (HPUs)

Construction Equipment

Industrial machinery

Agricultural machinery

Marine hydraulic systems

Injection molding machines