Flushing Line Oil Filter

Oil Flushing in the pipeline is the most common process in the industries that is performed immediately after shutdown. During this process, oil with high pressure and temperature is pumped into the line. The purpose of flowing lube oil with such high pressure and temperature is to create turbulence in the pipeline. This effect helps to dislodge contaminants stuck to the internal surface and carries them along with the running fluid. These contaminants include the pipe's internal metal rust and other solid particles. During the engine shutdown, this dirt stays in the pipeline.

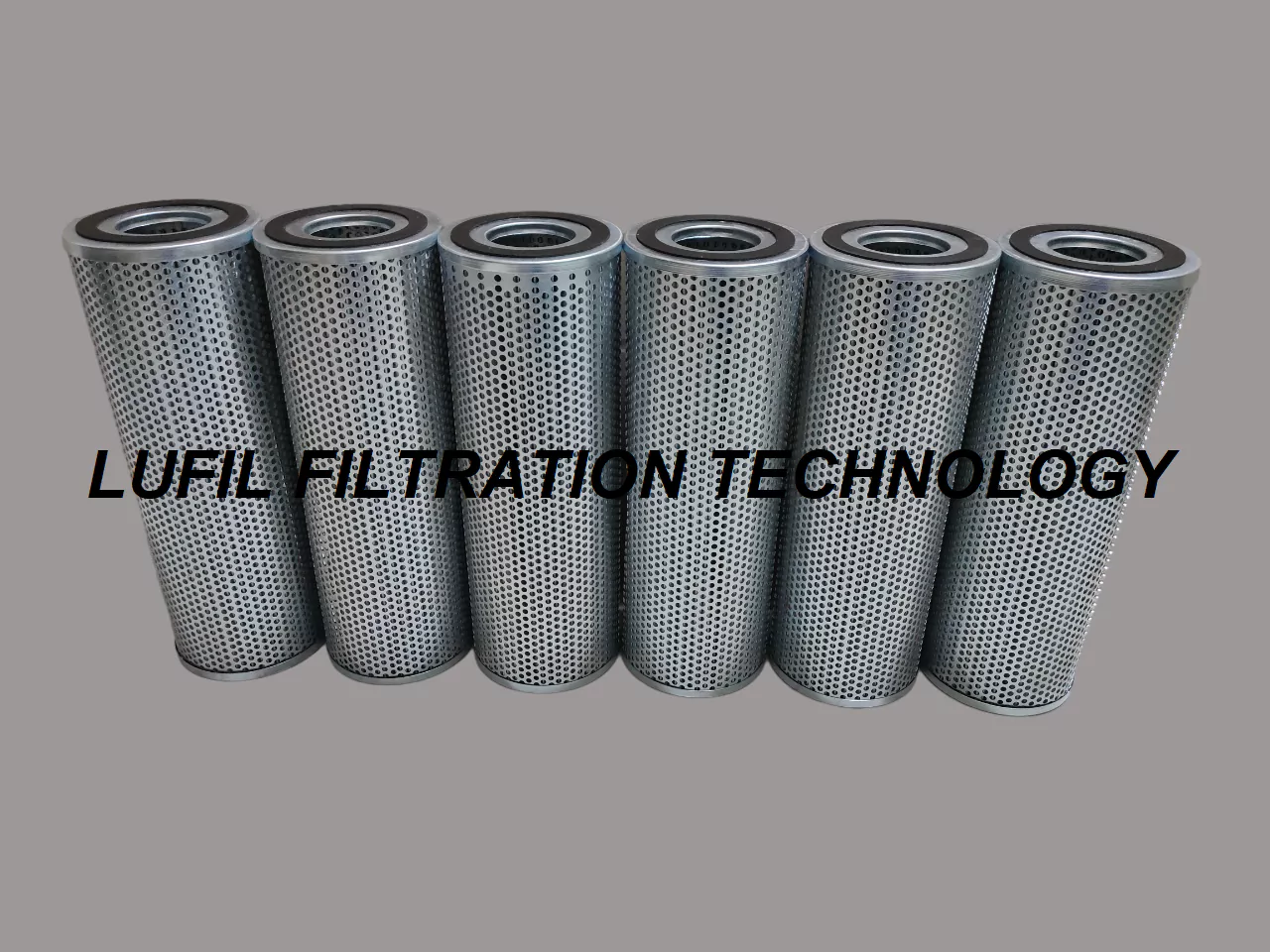

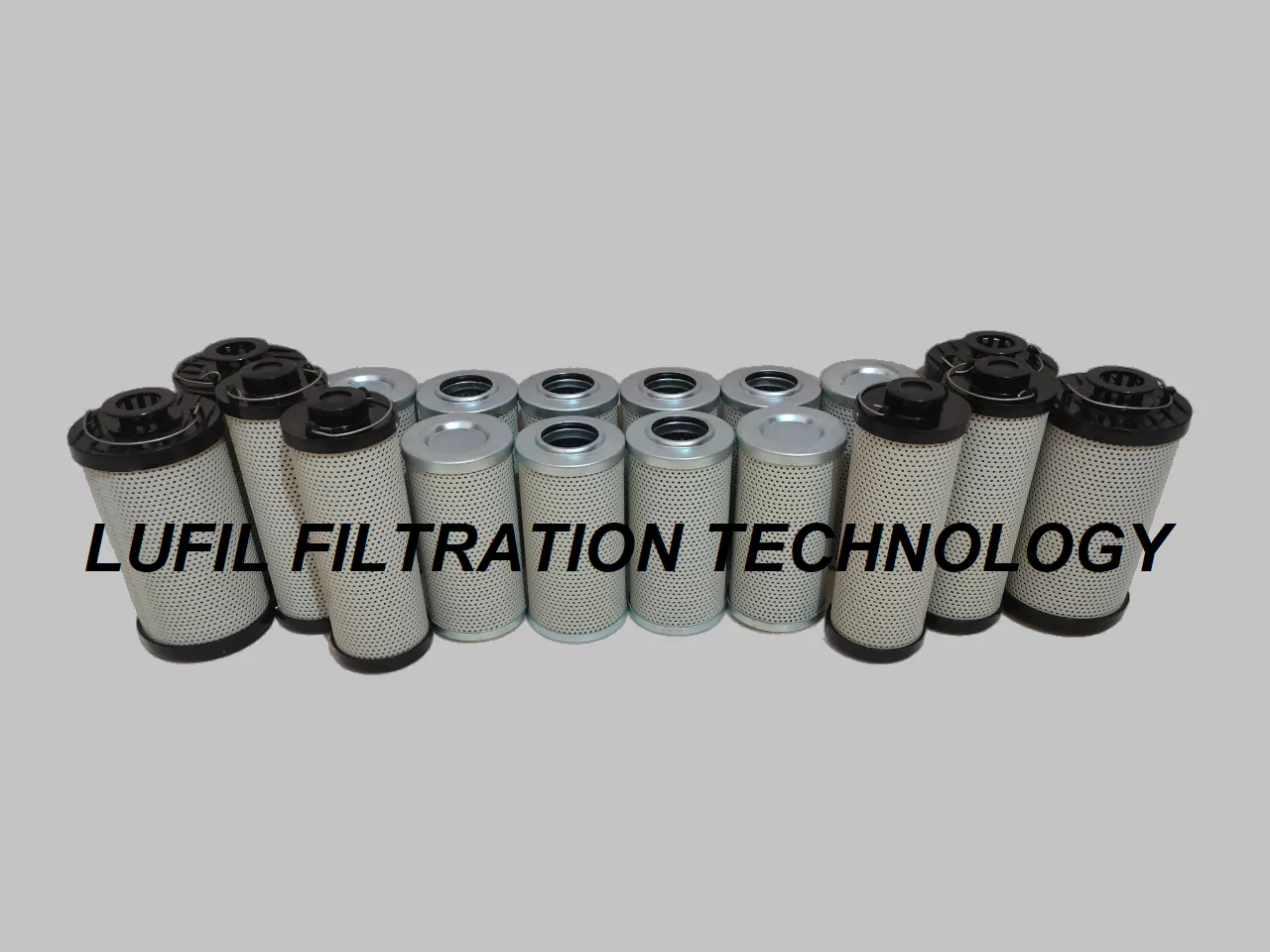

To trap such dust, flushing line oil filters are used to remove them effectively. Having a good filter cartridge in the system helps to maintain the equipment's life and improve its efficiency. These filters are manufactured using high grade synthetic glass fiber and stainless steel (SS) wire mesh material.

Wrap design elements are ideal for capturing larger micron particles when a smaller filtration area is needed. In contrast, pleated design elements are used to capture smaller micron particles and offer a higher filtration area.

Types of Filter Media Used in Oil Flushing Application

- Synthetic Oil Paper

Synthetic oil paper is a widely used material when it comes to use in flushing oil applications. Oil paper media provide higher dirt holding capacity than other materials. They are used when a nominal filtration rating is required. They come with beta ratings of 2, 50, 75. They are also cost effective compared to other filter media.

- Imported Glass fiber

The second commonly used media is fiberglass. Elements made from fiberglass are more efficient than other types, such as paper and wire mesh, for filtering fine dirt particles. They have beta ratings of 200 and 1000, depending on the required cleanliness level. In terms of efficiency, they can filter contaminants as small as 1 micron. Fiberglass media are also highly effective in high-temperature applications.

- Stainless Steel Wire Mesh

SS Wire mesh elements are used when reusability becomes the main aspect of an oil filter. They provide a nominal filtration rating and come with different micron and mesh sizes. Their wide range of mesh size availability makes them an ideal choice for using to remove higher micron dust.

Most Common Applications

Power Generation

Oil and Gas Industry

Manufacturing

Mining and Construction

Marine Industry

Textile Industry

Some of the Key Advantages Include

Efficient Contaminant Removal

Extended Equipment Life

Prevent Engine Breakdown

Sustain System Integrity

Maintain System Performance